After screw assembly, the assembled parts can be used as if they were a single part, meeting the highest requirements. The purpose of the screw in this process is to clamp the components tightly together so that they cannot be shifted by external forces. The obtained pre-load force has to be on the one side sufficient to hold the parts together, but on the other side, the screw and the parts should not be damaged by a force overload. The pre-load force is difficult to measure during mass-productions. Therefore, the torque or the angle are the predominant process variables.

The complexity to determine the correct torque or the suitable angle for an assembly and to fulfill the increased requirements in regards to process reliability, require the expert know-how for the design of the screwdriving tools and the process variables.

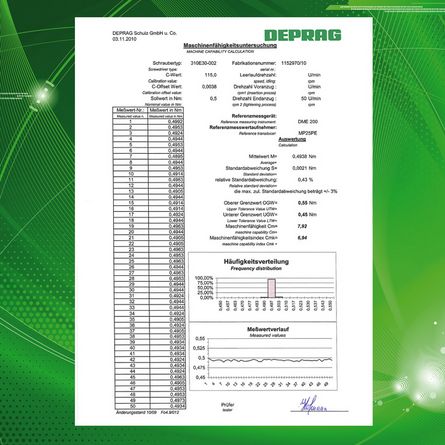

We gladly support your efforts by performing a comprehensive screw-joint analysis and a Machine Capability Study.

For your tools to continuously operate process reliable, we calibrate an exact torque and offer suitable test devices for their calibration. Additionally, we offer extensive training programs andmaintenance- and repair service.

Training / DEPRAG Academy

We offer a comprehensive training program where we teach the practical basics in the area of Screwdriving equipment.

Torque Adjustment

We gladly preset your screwdriver to a clearly defined torque.

Screw-joint Analysis

Which is the ideal torque for your screw assembly?

Which rotation speed should be applied?

What type of screwdriving tool best fits the task?

A screw-joint analysis assures the correct tightening parameter.

Machine Capability Study

An extensive inspection within the limits of a Machine Capability Study, takes place by means of regularly tested reference-transducers.

For electric tools, we can also offer a machine capability study for their angular-displacement.

Verification and realignment

The realignment of system components gives you the assurance that production resources will provide reliable screwdriving results.

Calibration Service

Calibration is not only a required regulation of the Norm DIN EN ISO 9001, but it also helps to guarantee the constant high quality of your product.

DEPRAG has an accredited, in house Calibration Laboratory, where for example DAkkS-calibrations according to DIN 51309 for passive transducers are performed.

Maintenance and Repair

DEPRAG gladly offers regular Maintenance and Repair for your Screwdiving equipment and feeding technology. We can quote cost-effective packages.